– https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data.

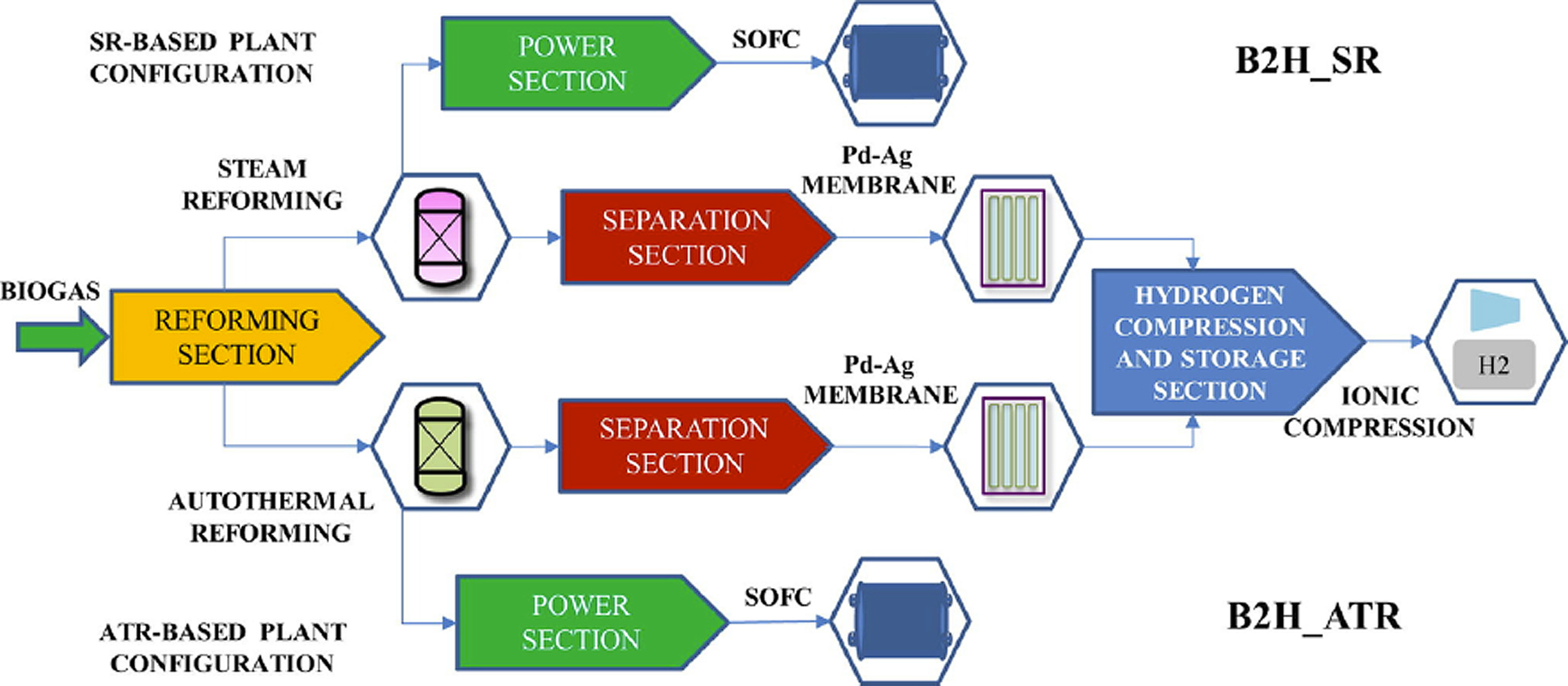

– M. Minutillo, A. Perna, A. Sorce, Appl. Energie 277 (2020) 115452.

– F.M. Baena-Moreno, D. Sebastia-Saez, L. Pastor-Pérez, T. Ramirez Reina, Renewable and Sustainable Energy Reviews 144 (2021) 110939.

– B. Teichgräber, A. Kraft, D. Rossol, M. Schröder, Green Hydrogen and Natural Gas from Digester Gas of Wastewater Treatment Plants, Proceedings of the WHEC, May 16.-21. 2010, Essen. ISBN: 978-3-89336-653-8.

– M. Reinders, P. Beckhaus, F. Illing, U. Misz , H. Riße, M. Schröder, P. Schulte, B. Teichgräber,

International Journal of Hydrogen Energy 40 (2015) 8601.

– M.J. Park, J.H Kim, Y.H. Lee, H.M. Kim, D.W. Jeong, Int. J. of Hydrogen Energy 45 (2020) 30188.

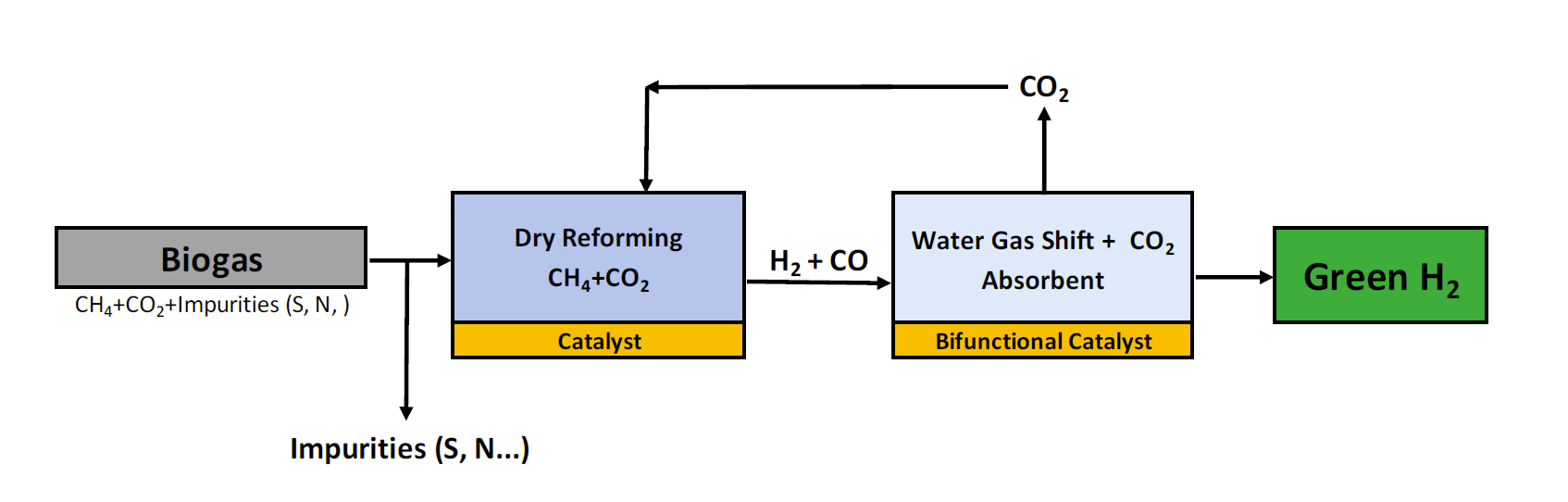

– R. García, M.V. Gil, F. Rubiera, D. Chen, C. Pevida, Energy 218(2021) 119491.

– F.M. Baena-Moreno, L. Pastor-Pérez, Q. Wang, T.R. Reina. J. Cleaner Production 265 (2020) 121909.

– L.N. Nguyen, J. Kumar, M.T. Vu, J.A.H. Mohammed, Nirenkumar Pathak, A.S. Commault, D. Sutherland, J. Zdarta, V. Kumar-Tyagi, L.D. Nghiem, Science of the Total Environment 765 (2021) 142753.

– M. Schäfer, O. Gretzschel, H. Steinmetz, Energies 13 (2020) 2088.

– S.E. Hosseini, Energy Conversion and Management 211 (2020) 112760.

– S.A. Chattanathan, S. Adhikari, M. McVey, O. Fasina, Int. J. Hydrogen Energy 39 (2014) 19905.

– P. Tarifa, N. Schiaroli, P.H. Ho, F. Cañaza, F. Ospitali, G. Sanghez de Luna, C. Lucarelli, G. Fornasari, A. Vaccari, A. Monzon, P. Benito, Catal. Today 2022 (383) 74.

– S. Jung, J. Lee, D.H. Moon, K.H. Kim, E.E. Kwon, Renewable and Sustainable Energy Reviews 143 (2021) 110949.

– E. Finocchio, T. Montanari, G. Garuti, C. Pistarino, F. Federici, M. Cugino, G. Busca, Energy Fuels 23 (2009) 4156–4159.

– P. Tu, D.N. Le, T.D. Dao, Q-T. Tran , T.C.D. Doan, Y. Shiratori, et al. Int. J. Hydrogen Energy. 45 (2020) 18363.

– Charisiou ND, Iordanidis A, Polychronopoulou K, Yentekakis IV, Goula MA. Materials Today:

Proceedings. 5 (2018) 27607-16.

– M.A. Goula, N.D. Charisiou, G. Siakavelas L. Tzounis, I. Tsiaoussis, P. Panagiotopoulou P, et al. Int. J. Hydrogen Energy. 42 (2017) 13724.

– T.G.H. Nguyen, D.L. Tran, M. Sakamoto, T. Uchida, K. Sasaki, T.D., et al. Int. J. Hydrogen Energy. 43 (2018) 4951.

– J.J. González-Pérez, J.F. Da Costa-Serra, A. Chica. Int. J. Hydrogen Energy. 45 (2020) 20568-20581.

– V.M. González-DelaCruz, J.P. Holgado, R. Pereñíguez, A. Caballero, J. Catal., 257 (2008) 307.

– A. Caballero, J.P. Holgado, V.M. González-delaCruz, S.E. Habas, T. Herranz, M. Salmeron, Chem. Commun., 46 (2010) 1097.

– R. Pereñíguez, V.M. González-DelaCruz, J.P. Holgado, A. Caballero, Appl. Catal.B: 96 (2010) 346.

– V.M. González-Delacruz, F.Ternero, R. Pereñíguez, A. Caballero, J.P. Holgado, Appl. Catal. A: General 384 (2010) 1.

– R. Pereñíguez, J.L. Hueso, J.P. Holgado, F. Gaillard, A. Caballero, Catal. Lett. 131 (2009) 164.

– V.M. Gonzalez-DelaCruz, R.Pereñíguez, F.Ternero, J.P. Holgado, A. Caballero, ACS Catal. 1 (2011) 82.

– Q. Sun, H. Li, J.L. Yan, Z. Yu, X. Yu. Renewable and Sustainable Energy Reviews. 51 (2015) 521-32.

– B. Bharathiraja, T. Sudharsanaa, A. Bharghavi, J. Jayamuthunagai, R. Praveenkumar. Biohydrogen and Biogas. Fuel. 16 (2016) 810-28. 13 de 35

– Y. Gao, J. Jiang, Y. Meng, F. Yan, A. Aihemaiti. Energy Conversion and Management. 171 (2018) 133.

– D.Y. Kalai, K. Stangeland, Y. Jin, W.M. Tucho, Z. Yu. International Journal of Hydrogen Energy. 43 (2018) 19438.

– P. Rosha, S.K. Mohapatra, S.K. Mahla, A, Dhir. Biomass and Bioenergy. 125 (2019) 70.

– B.W. Kwon, J.H. Oh, G.S. Kim, S.P. Yoon, J. Han, S.W. Nam, et al. Applied Energy 227 (2018) 213.

– Y.X. Zeng, L. Wang, C.F. Wu, J.Q Wang, B.X. Shen, X. Tu. Appl. Catal. B: Environm. 224 (2018) 469.

– K. Jabbour, A. Saad, L. Inaty, A. Davidson, P. Massiani, N. El Hassan. Int. J. Hydrogen Energy, 44 (2019) 14889.

– K. Bu, S. Kuboon, J. Deng, H. Li, T. Yan, G. Chen, et al. Appl. Catal B: Environm. 252 (2019) 86-97.

– P.H. Tu, D.N. Le, T.D. Dao, Q.T. Tran, T.C.D. Doan, Y. Shiratori, et al., Int. J. Hydrogen Energy. 45 (2019) 18363.

– H. Arbag. International Journal of Hydrogen Energy. 43 (2018) 6561-74.

– J.J. González-Pérez, J.F. Da Costa-Serra, A. Chica, Int. J. Hydrogen Energy, 45 (2020) 20568-20581.

– J.N.Armor, Appl.Catal.A, 176, 1999, 159.

– D.B.Levin, L.Pitt, M.Love, Int. J. Hydrogen Energy, 29, 2004, 173.

– H.A. Aleksandrov et al., Catal. Sci. Technol. 7, 2017, 3339.

– M. Akri et al., Nature commun. 10, 2019, 5181.

– M. Ryden, P. Ramos, Fuel Procces. Technolg. 96, 2012, 22736.

Nothing Found

Sorry, no posts matched your criteria